Discover the Benefits of Flexible Pipe Plumbing in Your Home

By:Admin

Company News & Blog

Top Manufacturers of Ceramic Lined Elbows in the Market

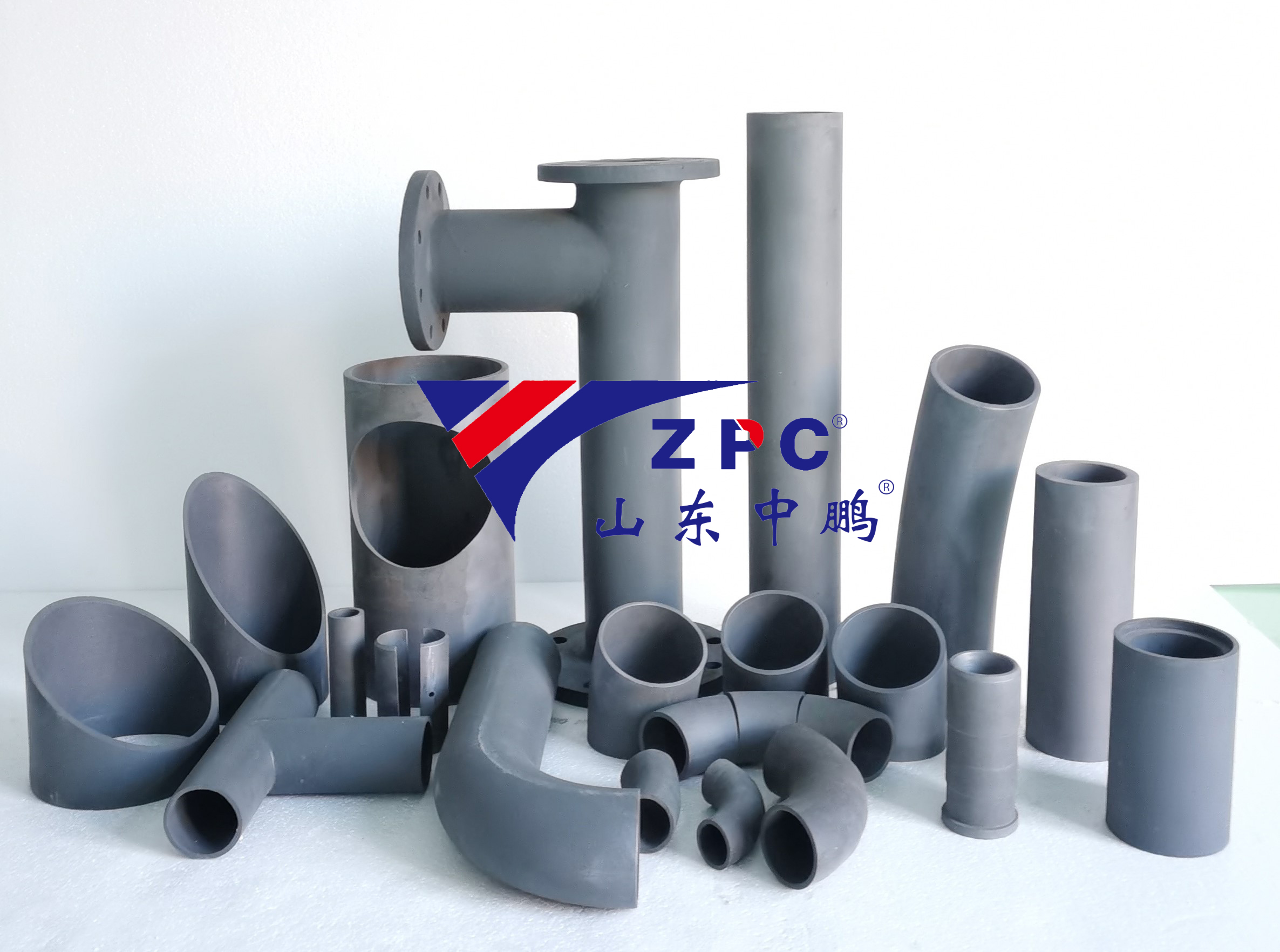

Ceramic Lined Elbow Factory Debuts Innovative Solution for Pipelines(City, Date) - In an effort to enhance pipeline performance and longevity, Ceramic Lined Elbow Factory has unveiled its latest innovation, a revolutionary ceramic lined elbow. This breakthrough technology is set to revolutionize the industry by providing superior protection against abrasion, corrosion, and erosion.Recognizing the need for durable and efficient solutions, Ceramic Lined Elbow Factory has invested considerable research and development efforts to engineer a high-quality ceramic lined elbow that surpasses existing industry standards. With its state-of-the-art manufacturing facility and a team of experienced professionals, the company aims to lead the market in providing innovative ceramic lining solutions for critical pipelines across various industries.Ceramic lined elbows offer substantial advantages over traditional piping systems, particularly in environments where high wear and tear are common occurrences. By integrating a smooth, dense ceramic lining into the elbow, the factory has created a wear-resistant product that significantly extends the life of pipelines.One of the key features of Ceramic Lined Elbow Factory's product is its unmatched resistance to abrasion, corrosion, and erosion. Unlike traditional materials, the ceramic lining prevents the build-up of solids and minimizes the impact of corrosive chemicals, thereby reducing maintenance costs and downtime. This can result in substantial savings for industries such as mining, power generation, and oil and gas.The high-quality ceramic lining also improves flow characteristics, reducing pressure drops and turbulence within pipelines. This not only leads to energy savings but also contributes to the overall efficiency of the transportation system. Moreover, the ceramic lined elbows can be customized to meet specific project requirements, ensuring a perfect fit and maximum performance.The manufacturing process at Ceramic Lined Elbow Factory involves precise engineering and quality control to ensure adherence to international standards. From the selection of premium ceramic materials to the meticulous inspection of final products, the factory prioritizes excellence at each stage. With advanced machinery and strict testing procedures, the company guarantees that every ceramic lined elbow leaving its facilities is of the highest quality.To better serve their clients, Ceramic Lined Elbow Factory offers comprehensive technical support and consulting services. Their experienced team is readily available to provide expert advice on product selection, installation techniques, and maintenance strategies. By cultivating long-term partnerships with customers, the factory aims to be a trusted industry leader in providing ceramic lined solutions that meet the unique needs of each project.As demand for reliable and efficient pipeline solutions continues to rise, Ceramic Lined Elbow Factory stands at the forefront of innovation. Their dedication to research and development, coupled with their commitment to delivering unparalleled quality, positions them as a preferred choice for industries seeking durable and cost-effective ceramic lined elbows.With their groundbreaking technology, Ceramic Lined Elbow Factory is transforming the pipeline industry, setting new standards for performance, and ensuring the longevity of critical transportation systems. As further advancements are made, the factory envisions a future where pipelines operate with optimal efficiency and minimal downtime, cementing their position as a trusted partner in global infrastructure development.About Ceramic Lined Elbow FactoryCeramic Lined Elbow Factory is a leading manufacturer of ceramic lined elbows located in (City, Country). With a commitment to innovation and excellence, the factory produces high-quality ceramic lined elbows that are renowned for their durability and wear-resistant properties. Backed by a team of experienced professionals and state-of-the-art manufacturing facilities, Ceramic Lined Elbow Factory aims to be a trusted industry leader in providing ceramic lined solutions for critical pipeline applications.

Reliable Fire Equipment Testing Services for Firefighters

Firefighters are the unsung heroes of our society. They put their lives at risk every day to protect us from the devastating effects of fires. To ensure that they are equipped with reliable and safe equipment, a thorough testing service is essential.Without doubt, testing plays a critical role in determining the safety and performance of firefighting equipment. The stakes are simply too high to leave anything to chance, which is why testing is so important. Helmets, in particular, are a key piece of equipment that need to be tested regularly. The ability of a firefighter's helmet to withstand intense heat and impact can mean the difference between life and death in the field.Firefighters across the globe rely on high-quality helmets and other firefighting apparatus to keep them safe and functional in the face of danger. Without proper testing, however, firefighters cannot be certain that their equipment will perform to the standards required to keep them safe. This is where fire equipment testing services come into play.A reputable fire equipment testing service provides comprehensive tests to determine the safety and effectiveness of firefighting apparatus. Testing services cover everything from helmets to fire hoses and ladders. Helmet fire test equipment is one of the most crucial elements of the testing process. It involves simulating extreme fire conditions to see how the helmet performs under pressure.Helmet fire test equipment includes specially designed chambers where helmets are exposed to intense flames and high temperatures. The test measures the helmet's heat resistance and impact absorption capabilities. A helmet that fails to meet the standards of the test is deemed unsafe and needs to be replaced.The importance of reliable helmet fire test equipment cannot be overstated. It helps firefighters feel confident that their equipment is up to the task of keeping them safe in the most hazardous situations imaginable. Without testing, firefighters would have no way of knowing whether their helmets would perform to the standards required in real-world situations.In summary, a reliable and reputable fire equipment testing service is essential to ensuring the safety and performance of firefighting equipment. For firefighters, knowing that their helmets and other gear have passed rigorous testing gives them the confidence to face any situation that comes their way. Helmet fire test equipment is just one small but vital element of the testing process that helps these brave first responders do their jobs safely and effectively.

Guide on selecting suitable chute liner for optimal performance

Choosing the right chute lining material is an essential step during the design consideration process. The selection of a suitable chute lining material can significantly impact the performance, durability, and maintenance requirements of the chute. In this blog post, we will discuss the importance of choosing the right chute lining material, specifically for coal chutes. Additionally, we will explore various factors that should be taken into account when selecting coal chute lining materials.Coal chutes are used in industries such as mining, steel, power generation, and cement manufacturing, where coal needs to be transferred from one location to another. These chutes are subjected to extreme conditions, including high abrasion, impact, and temperature variation. Therefore, it is crucial to choose a chute lining material that can withstand these challenges and provide maximum longevity.When selecting a chute lining material for coal chutes, the following factors should be considered:1. Abrasion resistance: Coal is a highly abrasive material and can cause significant wear and tear on chute surfaces. Therefore, the lining material should have excellent abrasion resistance to ensure prolonged service life.2. Impact resistance: Coal can also cause impact damage to chute surfaces, especially during the loading and unloading process. The lining material should possess good impact resistance to withstand such forces without cracking or breaking.3. Temperature resistance: Coal chutes are often exposed to high temperatures due to the combustible nature of coal. Therefore, the lining material should be able to withstand elevated temperatures without undergoing any structural or chemical degradation.4. Corrosion resistance: Coal contains sulfur and other corrosive elements that can lead to corrosion of metal chutes. Hence, it is advisable to choose a lining material that has excellent corrosion resistance properties to prevent any damage or deterioration of the chute structure.5. Material flow properties: The lining material should possess a smooth surface to promote the smooth flow of coal through the chute. Any rough surfaces or protrusions can cause material hang-ups or blockages, leading to production inefficiencies.Considering these factors, ceramic chute lining materials are often preferred for coal chutes due to their exceptional properties. Ceramic materials, such as alumina ceramics, offer superior abrasion resistance, impact resistance, and temperature resistance. They are extremely hard and can withstand the abrasive nature of coal, reducing wear and tear significantly. Alumina ceramics also have excellent high-temperature resistance, ensuring the longevity of coal chutes in industries where coal combustion occurs.Moreover, ceramic chute linings provide excellent corrosion resistance, eliminating the concerns related to corrosion caused by the sulfur content in coal. Their smooth surface properties help in reducing material hang-ups or blockages, improving the material flow efficiency. Additionally, ceramic linings can be easily customized and installed to fit specific chute designs.In conclusion, the selection of the right chute lining material is of utmost importance when designing coal chutes. Considering factors such as abrasion resistance, impact resistance, temperature resistance, corrosion resistance, and material flow properties, ceramic materials, especially alumina ceramics, are an excellent choice for coal chute linings. Their exceptional properties ensure extended service life, reduced maintenance requirements, and improved production efficiency. If you are looking for high-performance chute lining materials for your coal chutes, consider ceramic options to provide you with a reliable and long-lasting solution.

Discover the Benefits of Floor Heating Pipe for Your Home

[Company Introduction]The company is a leading manufacturer and supplier of floor heating pipes, providing innovative solutions for residential and commercial buildings. With a strong focus on quality and sustainability, the company has achieved remarkable success in the market. Their state-of-the-art manufacturing facilities and research centers ensure the development of superior products that meet the evolving needs of customers.The company has an extensive distribution network, enabling them to serve a wide range of clients globally. Their commitment to customer satisfaction, combined with the use of advanced technologies, has made them a preferred choice for floor heating solutions. Offering a diverse range of floor heating pipes, they cater to both new constructions and retrofit projects.[News]Title: Innovation in Floor Heating Pipe Technology Sets New Industry Standards[Subtitle] Leading Manufacturer Unveils Next-Generation Floor Heating Pipe[date][city, country] – The floor heating industry is set to witness a revolutionary change with the launch of an advanced floor heating pipe by a leading manufacturer. The innovation marks a significant milestone in the quest for creating more energy-efficient and sustainable solutions for residential and commercial buildings.Designed with cutting-edge technology and engineering expertise, the latest floor heating pipe by the company promises superior performance and durability. The innovative features and enhanced functionalities of the product are poised to set new industry standards, enabling customers to achieve optimal comfort while significantly reducing energy consumption.One of the key highlights of the new floor heating pipe is its improved heat transfer efficiency. Through extensive research and development, the company has successfully incorporated advanced materials and design techniques that maximize the transmission of heat. This innovative approach allows for faster and more efficient heating, resulting in reduced overall energy consumption.Moreover, the floor heating pipe integrates a state-of-the-art flow control system that ensures uniform heat distribution throughout the space. This cutting-edge feature eliminates any hot or cold spots, providing a consistent and comfortable temperature in all areas. Whether installed in residential homes or commercial complexes, this advancement in technology guarantees a superior heating experience for end-users.Apart from its functional benefits, the new floor heating pipe is also environmentally friendly. Manufactured using sustainable materials, it aligns with the company's commitment to minimizing the carbon footprint. By opting for this innovative solution, customers contribute to a greener future while enjoying the economic advantages of reduced energy costs.The launch of the new floor heating pipe has generated significant interest among professionals in the construction and HVAC industries. Its groundbreaking attributes and potential for energy savings have positioned it as a game-changer in the market. Architects, engineers, and contractors are eagerly awaiting the opportunity to incorporate this innovative product into their designs and projects.As the floor heating industry continues to evolve, this breakthrough in technology sets a new benchmark for efficiency and sustainability. With its commitment to research and development, the company ensures that its products remain at the forefront of innovation. The launch of the advanced floor heating pipe represents a significant step towards creating a more comfortable, cost-effective, and environmentally friendly heating solution for buildings worldwide.About [Company][Company] is a renowned manufacturer and supplier of floor heating pipes that specializes in providing cutting-edge solutions for residential and commercial applications. With a reputation for quality and innovation, the company has become a preferred choice for professionals in the construction and HVAC industries. By leveraging advanced technologies and sustainable practices, [Company] remains committed to revolutionizing the floor heating industry and providing customers with superior products.

New Arrival: High-Quality Oxidation Firing Nitride-Bonded Silicon Carbide Plate for Ceramic Kiln

When it comes to high-temperature firing in ceramics, the choice of kiln shelf is crucial. And that's where oxide firing nitride bonded silicon carbide plates, also called SiC batts, come in. These are high-quality kiln shelves that are designed to provide excellent heat resistance and durability to withstand the intense firing process.At Jiaozuo Beixing Refractories Co., Ltd., we offer the latest oxide firing nitride bonded silicon carbide plates as a wholesale supplier from China. Our SiC batts come with many benefits that make them a superior choice for high-temperature firing applications.One of the most significant advantages of SiC batts lies in their excellent thermal conductivity. SiC is known to have a high thermal conductivity, which means that it can transfer and distribute heat evenly across the surface. This makes it ideal for use in kilns, where the high temperature can cause rapid and uneven heat transfer.SiC batts are also highly resistant to thermal shock, which means they can withstand sudden temperature changes without cracking or breaking. This is a critical factor as kiln firing involves exposing the ceramic ware to extreme heat temperatures throughout multiple stages in the firing process.Another critical feature of SiC batts is their outstanding resistance to oxidation. When exposed to high temperatures and oxygen, several materials begin to break down and corrode. However, SiC's chemical composition makes it one of the most oxidation-resistant materials, making it perfect for use in high-temperature firing applications.At Jiaozuo Beixing Refractories Co., Ltd., we offer SiC batts in a range of sizes and thicknesses to suit different kiln types and firing needs. We also customize SiC batts to meet our customers' specific requirements.SiC batts from Jiaozuo Beixing Refractories Co., Ltd. are a reliable and cost-effective solution for high-temperature firing applications. Whether you're an artist, hobbyist, or professional ceramicist, our SiC batts will help you achieve the consistent and high-quality results you need.In conclusion, when it comes to high-temperature ceramic firing, oxide firing nitride bonded silicon carbide plates, or SiC batts, are the way to go. They offer excellent thermal conductivity, thermal shock resistance, and oxidation resistance, making them the best choice for kiln shelves. So, if you're looking for high-quality SiC ceramic kiln shelves and plates, Jiaozuo Beixing Refractories Co., Ltd. has got you covered.

Comparing LPG and Natural Gas Jet Nozzles: Which is More Efficient?

Title: Leading Energy Solutions Provider Introduces Next-Generation Jet Nozzle for LPG or NGIntroduction:In a groundbreaking development, a renowned energy solutions provider has unveiled its latest innovation in the form of a cutting-edge jet nozzle designed for use with Liquefied Petroleum Gas (LPG) or Natural Gas (NG) fuels. This exceptional company, with a diverse portfolio of high-performance products, has once again shown its commitment to revolutionizing the energy industry with its state-of-the-art technology. The newly introduced LPG or NG jet nozzle promises enhanced performance and efficiency, contributing to a cleaner and more sustainable future.Body:1. Introduction to the Company:With a rich history spanning over several decades, the company has solidified its position as a key player in the energy sector. Renowned for its unwavering dedication to research, development, and innovation, the company embodies excellence and serves customers across numerous industries globally. Their wide range of products guarantees optimal performance, efficiency, and environmental sustainability.2. The Need for Advanced Jet Nozzles:As the demand for cleaner and more efficient fuel sources continues to rise, so does the importance of developing advanced jet nozzles to ensure optimized combustion. LPG and NG have gained popularity due to their lower carbon emissions and cost-effectiveness. The introduction of an innovative jet nozzle specifically tailored for these fuels fills a critical gap in the market.3. Cutting-Edge Design and Functionality:The newly unveiled LPG or NG jet nozzle boasts a meticulously crafted design, incorporating state-of-the-art features that enhance fuel atomization, combustion efficiency, and overall performance. Its robust construction ensures durability, even under demanding operating conditions. The nozzle's advanced design guarantees a stable and consistent fuel-air mixture, facilitating maximum combustion efficiency and minimizing pollutant emissions.4. Enhanced Performance and Efficiency:This next-generation jet nozzle is engineered to deliver unparalleled performance, resulting in improved energy efficiency and reduced fuel consumption. By ensuring precise fuel atomization, the nozzle optimizes combustion, minimizing wastage and maximizing thermal efficiency. The innovative design also promotes cleaner combustion, leading to lower emissions of greenhouse gases and air pollutants.5. Versatility and Adaptability:A notable advantage of the LPG or NG jet nozzle is its outstanding versatility and adaptability, making it compatible with a wide range of applications. From industrial heating systems to residential cooking appliances, this nozzle's design allows for seamless integration across various equipment, meeting the diverse needs of end-users.6. Environmental Sustainability:As the world strives to combat climate change and reduce carbon footprints, the introduction of the LPG or NG jet nozzle is a significant step towards a greener future. By promoting efficient combustion and reducing emissions, this advanced nozzle aligns perfectly with global sustainability goals. Its adoption can contribute to improved air quality and a healthier environment.7. Industry Applications and Economic Benefits:Industries like automotive, heating, cooking, and power generation can benefit immensely from the cutting-edge LPG or NG jet nozzle. This technology empowers businesses to meet stringent environmental regulations while enjoying increased operational efficiency and reduced fuel expenditures. By combining sustainability and cost-effectiveness, this nozzle presents an attractive solution to organizations seeking enhanced performance and economic benefits.Conclusion:With the launch of their groundbreaking LPG or NG jet nozzle, this leading energy solutions provider once again demonstrates its unwavering commitment to technological innovation and sustainable practices. The advanced design, efficiency, and versatility of the nozzle position it as a game-changer in the energy industry. By facilitating cleaner combustion and reducing emissions, this next-generation jet nozzle paves the way for a greener and more sustainable future.

Nasdaq-listed home interiors company sees boost in stock prices

SiC tile, also known as silicon carbide tile, is a high-performance ceramic material that is used in a variety of applications. Its unique properties make it an attractive choice for various industrial processes, including ballistic armor, aerospace, and electronics.SiC tile is engineered to withstand extreme temperatures, harsh chemicals, and even impacts from high-velocity projectiles. Its unique combination of strength, durability, and thermal conductivity make it a standout material for a wide range of applications, especially those that require high levels of performance under challenging conditions.One of the primary uses for SiC tile is in ballistic armor. Due to its exceptional hardness and strength, SiC tile is incredibly effective at stopping bullets and other projectiles. In fact, it is often used in conjunction with Kevlar to create a lightweight, yet incredibly strong, armor system for military and law enforcement personnel.In addition to its use in armor, SiC tile is also employed in the aerospace industry. Its high thermal conductivity and excellent resistance to oxidation make it an ideal material for use in the hot sections of jet engines. In these high-temperature environments, SiC tile offers superior performance compared to other materials, resulting in increased efficiency and longer engine lifetimes.SiC tile is also utilized in the electronics industry. Its unique properties make it an attractive choice for use in high-power electronic devices, such as power inverters and high-frequency amplifiers. In these applications, SiC tile offers better thermal management than traditional materials, resulting in increased reliability and improved performance.As the demand for high-performance materials continues to grow, SiC tile is poised to become an increasingly important component across a wide range of industries. Its unique properties make it an attractive choice for a diverse array of applications, from armor to aerospace and beyond.In conclusion, SiC tile is a high-performance ceramic material that offers exceptional strength, durability, and thermal conductivity. Its unique properties make it an attractive choice for a wide range of applications, including ballistic armor, aerospace, and electronics. As the demand for high-performance materials continues to expand, SiC tile is poised to become an increasingly important component across a wide range of industries.

Rugged and Durable Silicon Carbide Products: Beams, Plates, Rollers, and More by IPS Ceramics

Silicon Carbide Rollers: The Rugged and Dependable PerformerWhen it comes to high-temperature applications, the choice of materials for manufacturing various components becomes critical. Silicon Carbide (SiC) is a popular material of choice due to its excellent properties and performance in high-temperature environments. Silicon Carbide Rollers are one such application where the material's superior properties and performance make them rugged and dependable performers for many industrial processes.IPS Ceramics offers various types of Silicon Carbide products, including beams, batts, plates, and rollers, specifically designed to cater to different application requirements. The use of Silicon Carbide has become increasingly prevalent in recent years, owing to its exceptional thermal properties, high strength, and resistance to wear and chemical corrosion.The Silicon Carbide Rollers' unique properties make them ideal for use in heat-treatment processes and kiln firing applications, where temperatures may exceed 1500 ℃. The rollers' ability to withstand high temperatures without bending or warping makes them an invaluable component in industrial processes. Silicon Carbide Rollers are impervious to chemical attacks and provide reliable support to the products being processed, ensuring the consistent and uniform heating and cooling of products that are essential to many industries.The high strength and wear resistance of Silicon Carbide Rollers make them durable and minimize the need for frequent replacements. These properties reduce production downtimes and costs and increase overall efficiency, making them a popular choice among manufacturers.IPS Ceramics offers Silicon Carbide Rollers in various dimensions, shapes, and specifications, making them adaptable to different requirements. Our team of experts has experience in designing and manufacturing Silicon Carbide Rollers that cater to specific industrial processes' needs.The use of Silicon Carbide Rollers is not limited to heat-treatment processes alone. They are also widely used in glass manufacturing, steel production, and various thermal processing applications. Their robustness, high thermal conductivity, and low thermal expansion make them ideal for use in these applications, ensuring that products remain stable throughout the manufacturing process.To conclude, the Silicon Carbide Rollers' rugged and dependable performance make them an invaluable component in many industrial processes. Their superior properties make them the material of choice for manufacturers looking for longevity, reliability, and performance from their equipment. IPS Ceramics provides a wide range of Silicon Carbide Rollers that meet the specific needs of various industrial applications. With our expertise, we can assist manufacturers in selecting the right Silicon Carbide Rollers for their manufacturing processes. For all your Silicon Carbide Roller requirements, contact IPS Ceramics today!

Two Contract Workers Suffer Severe Burns After Liquid Metal Spill at Steel Plant in Visakhapatnam

Working in a steel plant can be a challenging task as it involves handling heavy machinery and hazardous materials. One such incident happened recently where two contract workers suffered severe burns due to liquid metal spillage. The incident occurred in the SMS unit of a steel plant in Visakhapatnam.It is reported that the workers were performing their duties when suddenly liquid metal spilled on them. While some workers escaped with minor injuries, two workers sustained severe burns. The cause of the accident was the failure of the burner nozzle. When the nozzle failed, it caused a leakage of liquid metal, which resulted in the accident.Burner nozzles are essential components in steel plants as they help in the production of hot and molten metals. They are used to inject fuel and air into the furnace to generate high temperatures. If the burner nozzle is not functioning correctly or has any faults, it can lead to accidents such as the one that occurred in this steel plant.Steel plants are known for their high-risk working environments, and accidents are common. However, companies can take measures to reduce the risk of such accidents. Proper training should be provided to all workers involved in handling machinery and hazardous materials. Workers should be equipped with the necessary safety gear such as helmets, gloves, and protective clothing.Regular maintenance and inspection of machinery and equipment should be carried out to ensure their proper functioning. This can prevent accidents caused by faulty machinery. It is also essential to create a culture of safety in the workplace, where workers are encouraged to report any hazards or faults in machinery.In conclusion, accidents can happen in any workplace, but they can be avoided by taking proper safety measures. The incident in the steel plant in Visakhapatnam highlights the importance of ensuring the proper functioning of machinery and equipment in high-risk environments. Burner nozzles play a crucial role in steel plants, and their maintenance and inspection are necessary to prevent accidents. By implementing safety measures, companies can provide a safer working environment for their employees, reducing the risk of accidents.