In any industrial heating process perhaps the most critical aim is to provide a carefully controlled temperature profile within the kiln or furnace. Whether the fuel is natural gas, LPG or oil, the location of the burners is a potential hot-spot within the kiln. Burner flames can be long enough to make contact with the product or kiln furniture causing very severe over-heating which is damaging to both. Even when the exposed flame is kept at a safe distance, direct radiant heating can cause localised over-heating of product and subsequent quality problems. Burners that use silicon carbide tubes offer several advantages:-

In any industrial heating process perhaps the most critical aim is to provide a carefully controlled temperature profile within the kiln or furnace. Whether the fuel is natural gas, LPG or oil, the location of the burners is a potential hot-spot within the kiln. Burner flames can be long enough to make contact with the product or kiln furniture causing very severe over-heating which is damaging to both. Even when the exposed flame is kept at a safe distance, direct radiant heating can cause localised over-heating of product and subsequent quality problems. Burners that use silicon carbide tubes offer several advantages:- Silicon Carbide Burner Nozzles

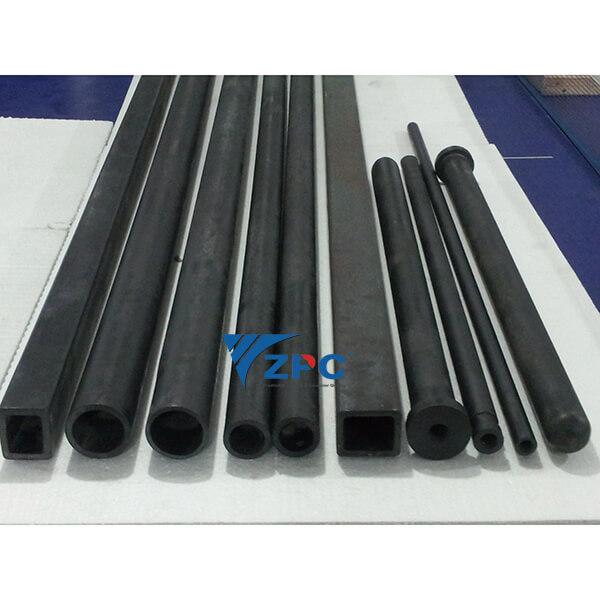

The tube forms a chamber within which most of the combustion takes place. Only a minimal amount of flame is directly exposed to the kiln load, almost eliminating radiant hot-spots. The tube exit is normally tapered to increase exhaust velocities. Greater velocities improve mixing within the kiln, improving temperature uniformity. Greater exhaust velocities also increase the entrainment of kiln atmosphere from around the burner, diluting the hot exhaust stream and ensuring rapid energy transfer. ZPC Ceramics can now offer most sizes of silicon carbide tube to match your existing kiln burners. • High quality material giving a long service life • Low thermal expansion and high conductivity gives exceptional resistance to thermal shock cracking • Dimensionally stable with no significant deformation and creep • Resistant to oxidation and corrosion • No burner quarl is required. • Suitable for both brick or fibre linings • Used in most kilns types – tunnel, roller and shuttle SiC is recommended for most kilns and furnaces working below 1350℃.SiC radiation pipes

SiC radiation pipes have superior characteristic such as corrosion resistance, high temperature tolerance, oxidation resistance, superior thermal conductivity, bending strength, long time service life, etc. They are also very efficient, energy-saving, enviromental protection in the field of industrial production. The series of radiation pipes are widely used in the annealing production lines for industries of steels and metallurgies. They are also used for heat conduction system and radiant system under the conditions of high temperature, high corrosion and high wear resistance. SiC is recommended for most kilns and furnaces working below 1350℃.