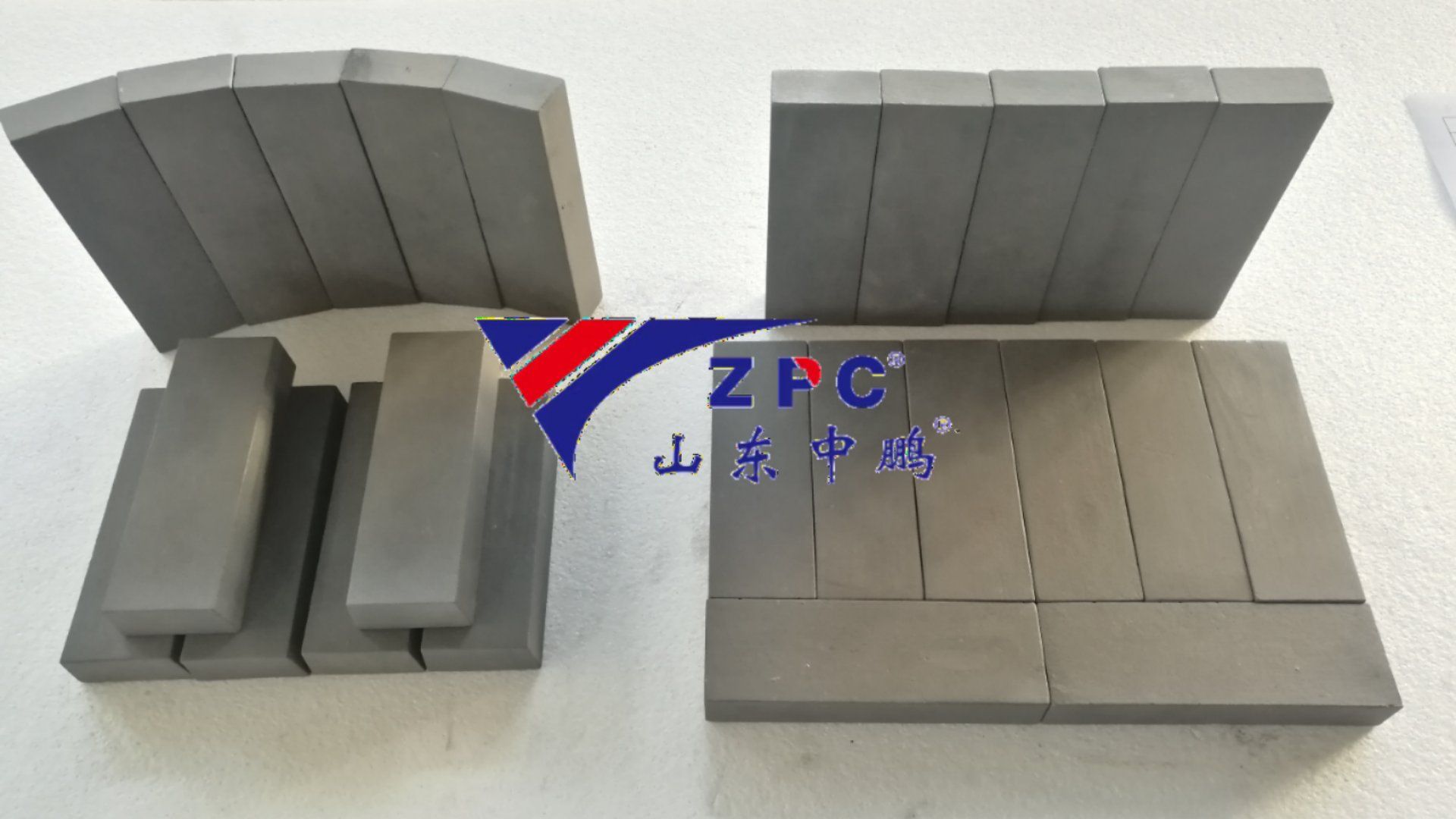

Special Shape Silicon Carbide New Material Ceramic

We are a factory specializing in Special Shape Silicon Carbide New Material Ceramic manufacturing. Our high-quality products offer superior strength and durability. Contact us for a reliable and cost-effective solution.

Request a QuotePRODUCTS DETAILS

Hot Products

Wear resistant domal bodies

DN50 Single direction Sic Nozzle

Wear Resistant Silicon carbide SiC cylinder, cone, spigot manufaturer factory in China, Africa, Australian, Asia

Scrubber Nozzles: SiC Absorber Spray Nozzles

wear resistant silicon carbide ceramic tiles

Flue Gas Desulfurization Spray Nozzle

hydrocyclone silicon carbide cone lining and apex liner factory

Wear resistant,high temperature resistant and corrosion resistant ceramic lined pipes

92% Alumina tiles and pipe Linings - ceramic lined wear-resistant pipe

Silicon Carbide of Vickers Hardness of 2000kg/mm2, offers superior protection for sliding abrasion applications

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours